Automated welding system design

Tailor-made turnkey automated machinery:

choose Tecsal to optimise your production

Machining processes

Not only welding: our machinery can perform any type of process and merge several processes in the same machinery to return finished products.

However, our aptitude for welding solutions also allows us to provide specific advice on welding processes, combining training and many years of experience.

Handling

Cutting

Assembly

Loading / Unloading

Pallettising

You don't need many systems: one is enough

Designing several systems for individual applications can be costly and may not be the most efficient and effective solution. With a custom-made design, a single welding system can be built that brings together all the necessary types of processing. Process automation ensures repeatable, precise, quality processing that minimises waste.

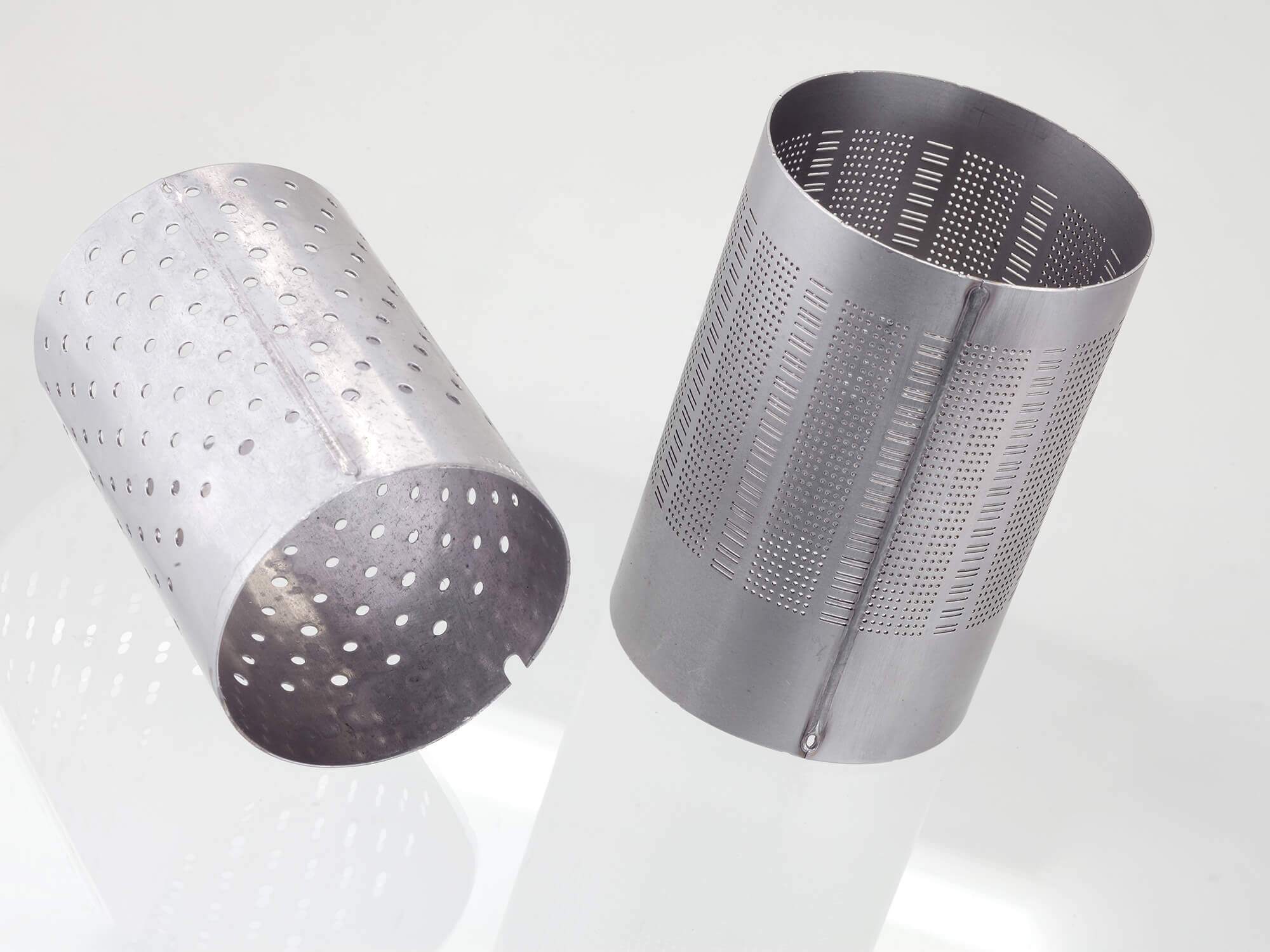

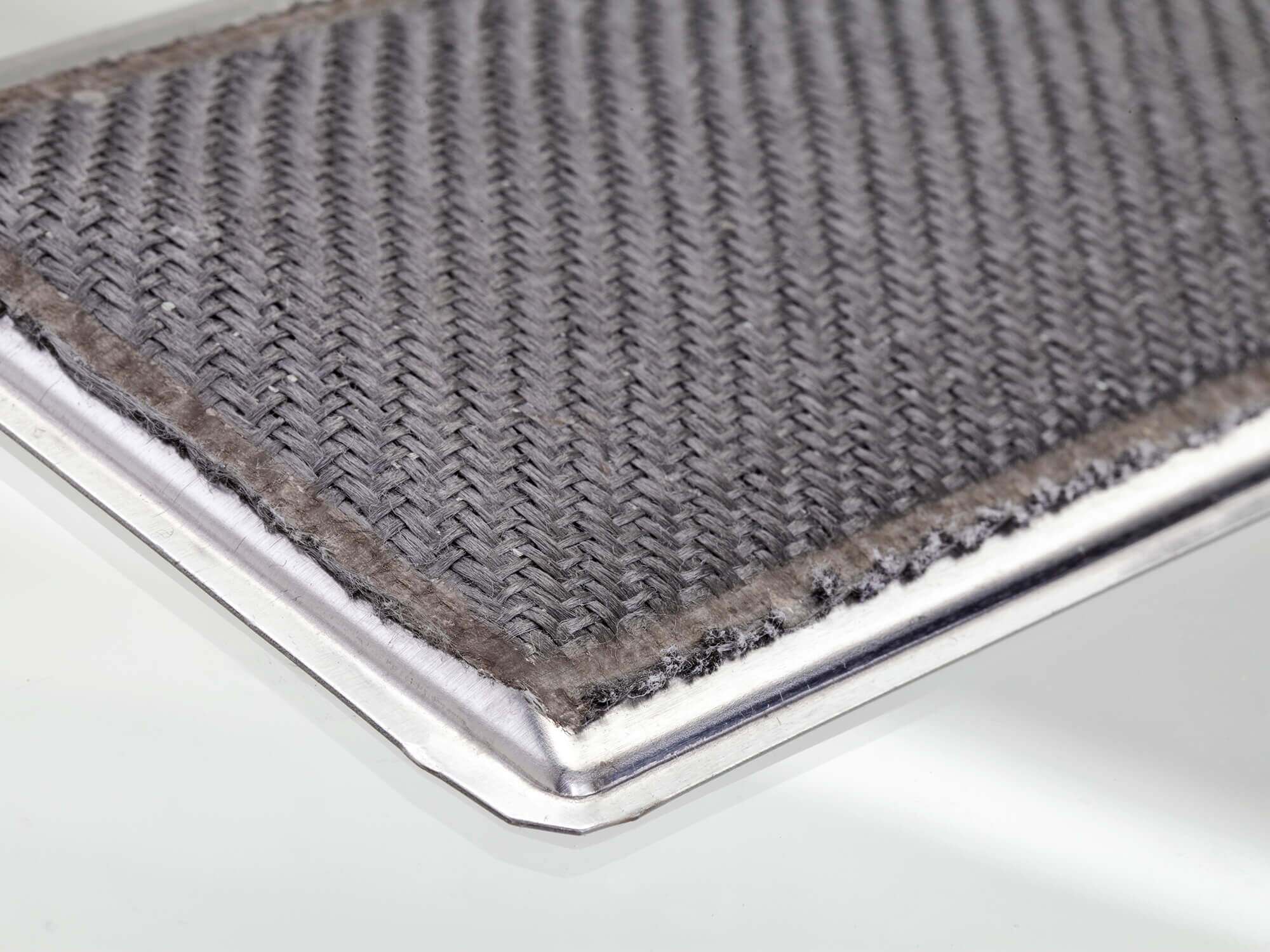

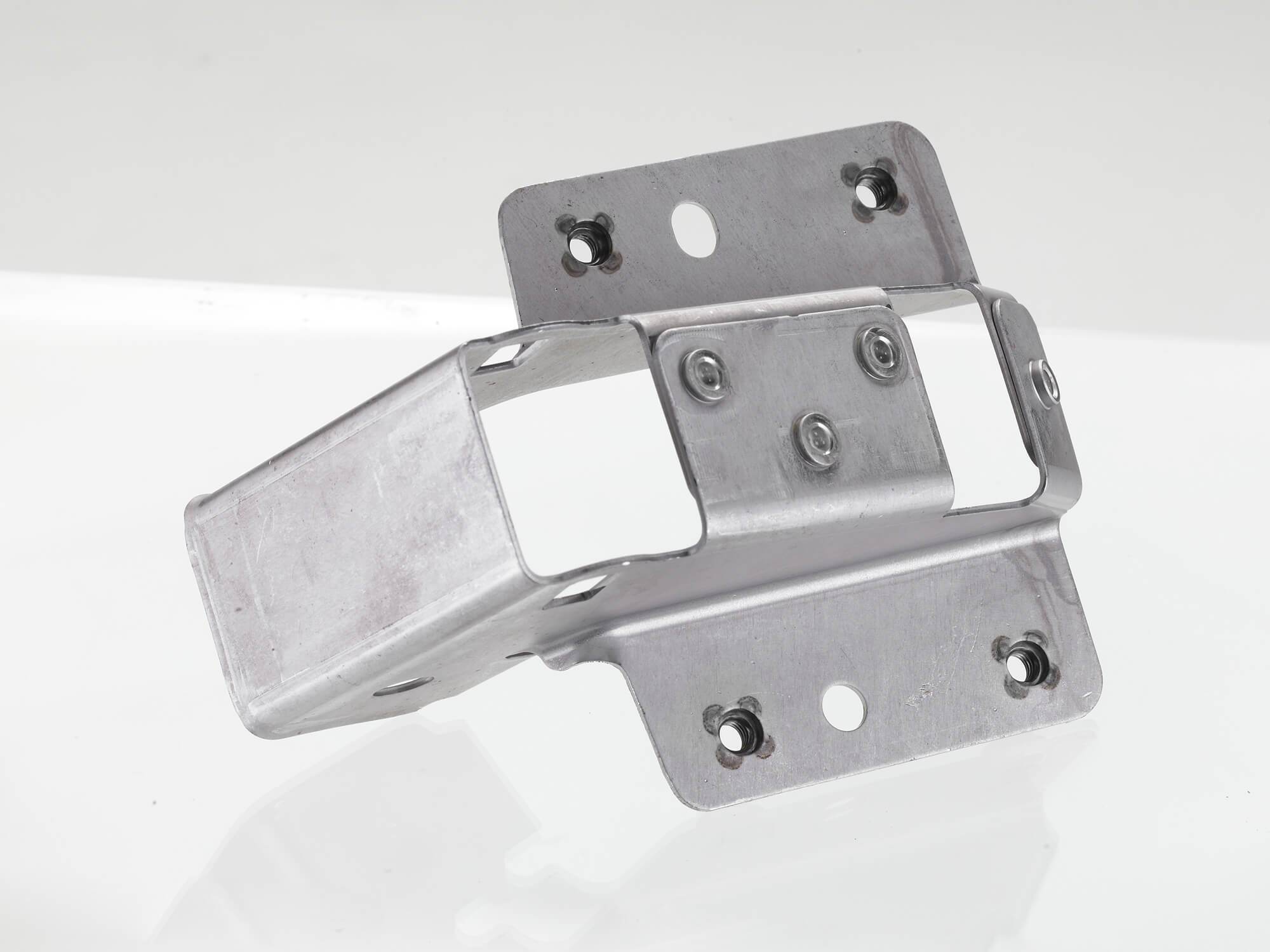

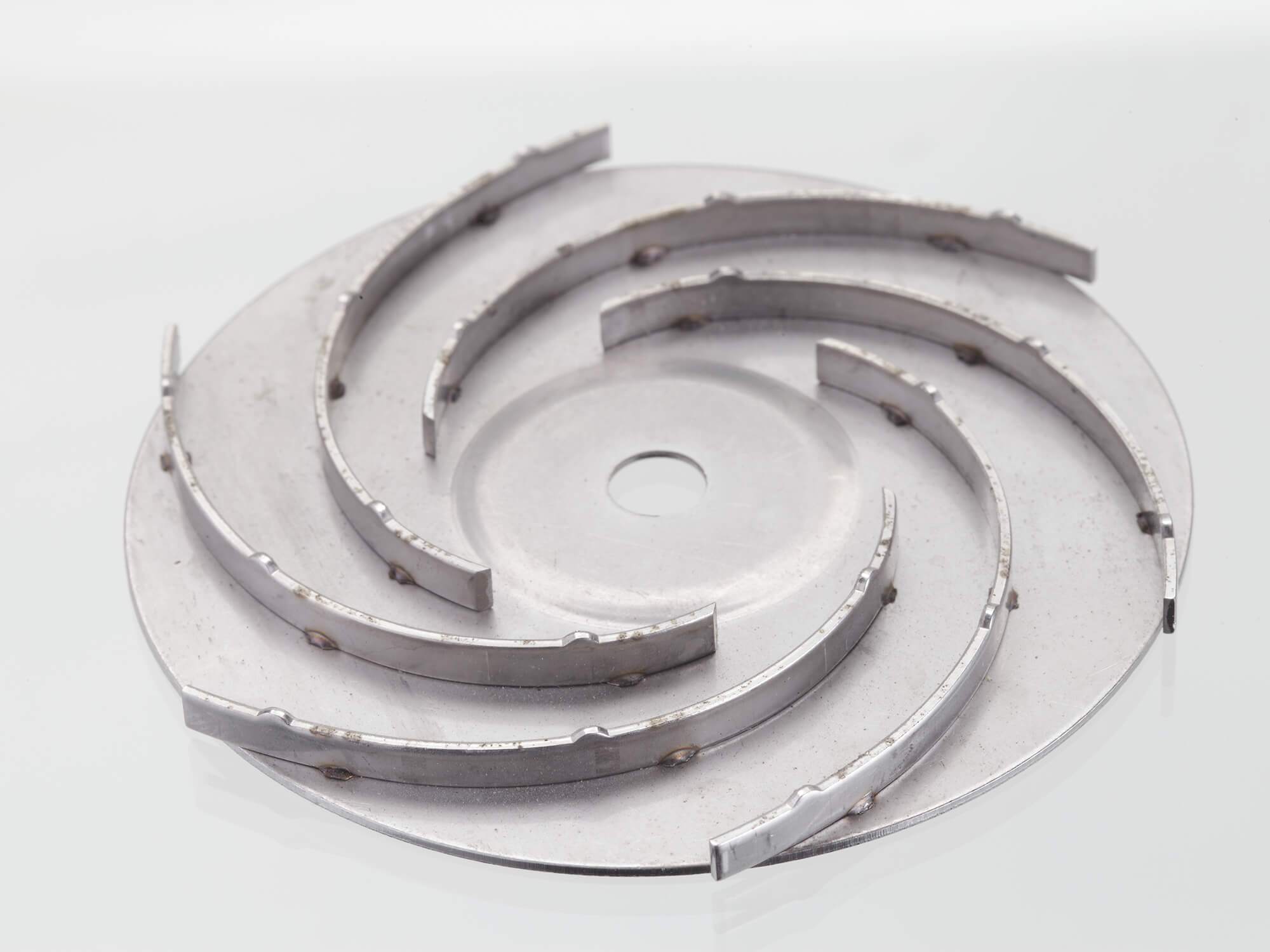

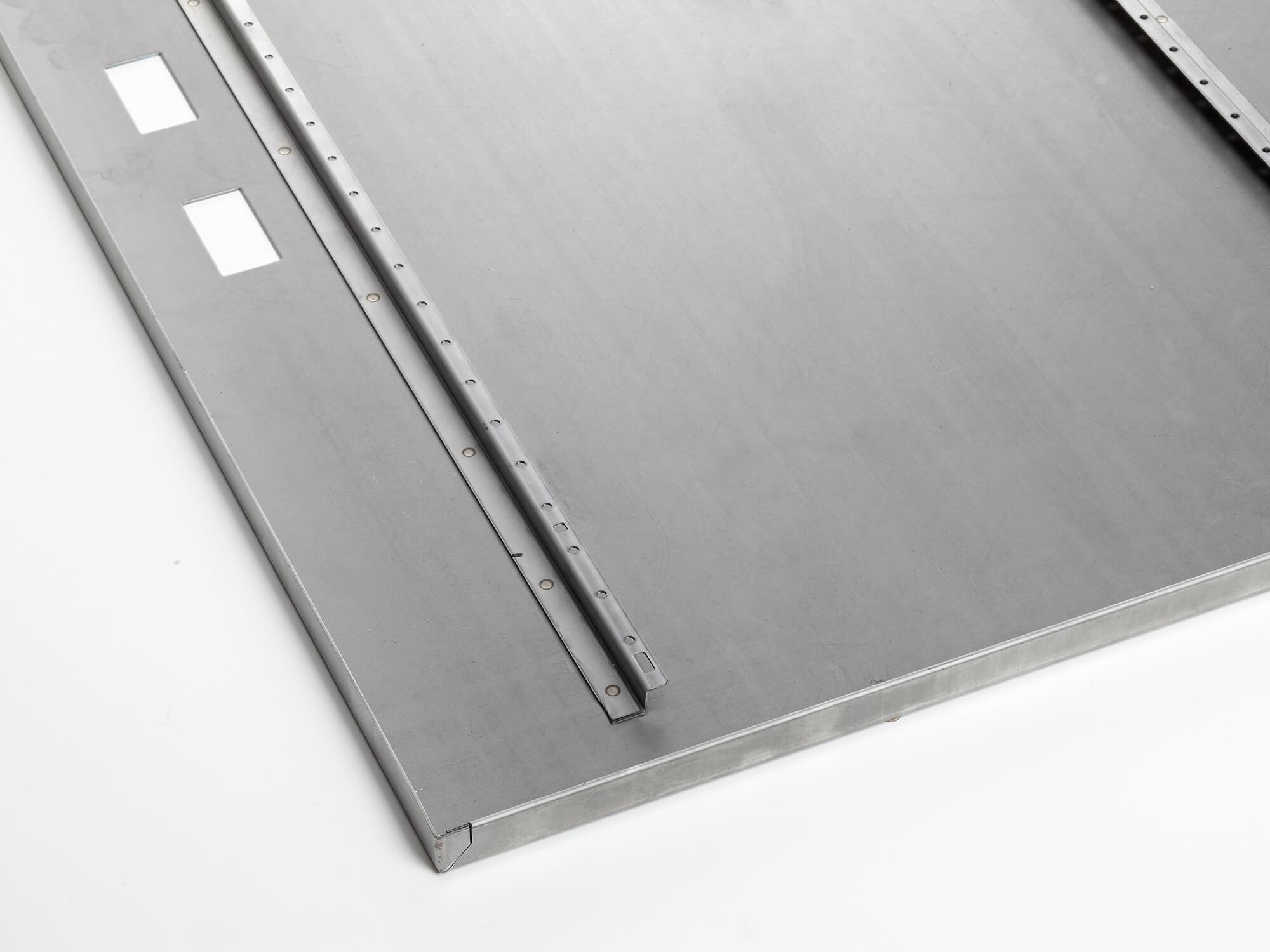

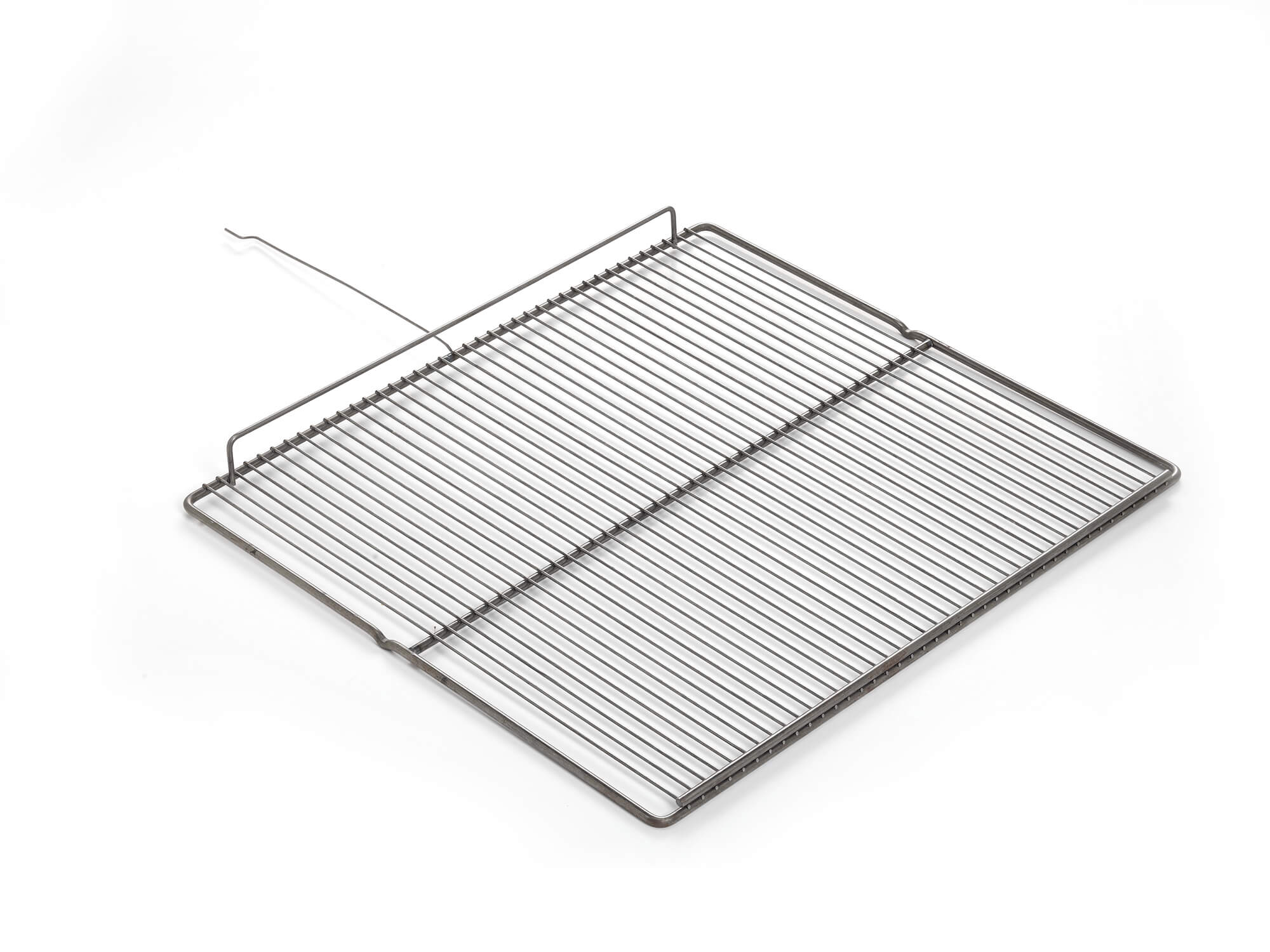

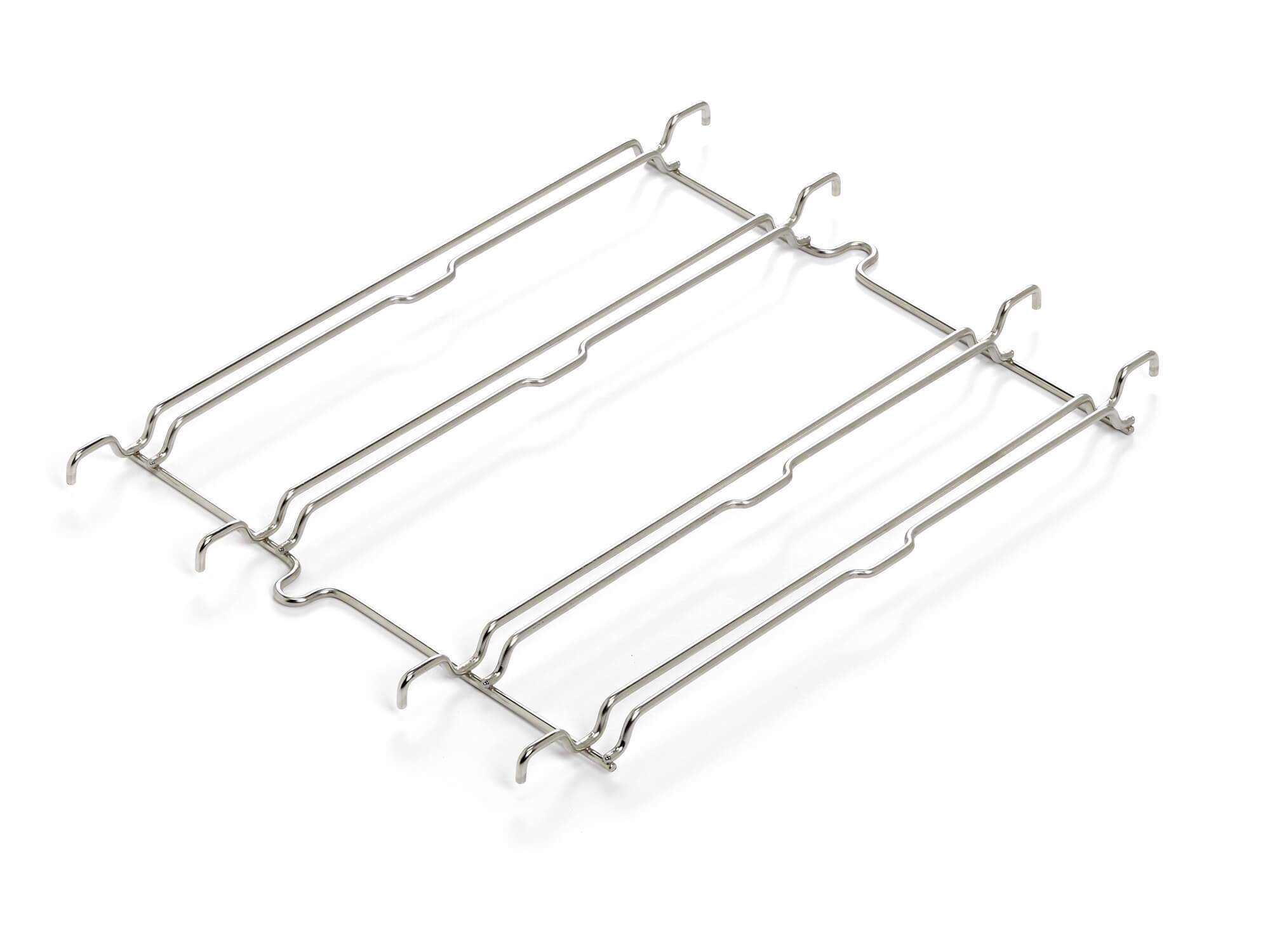

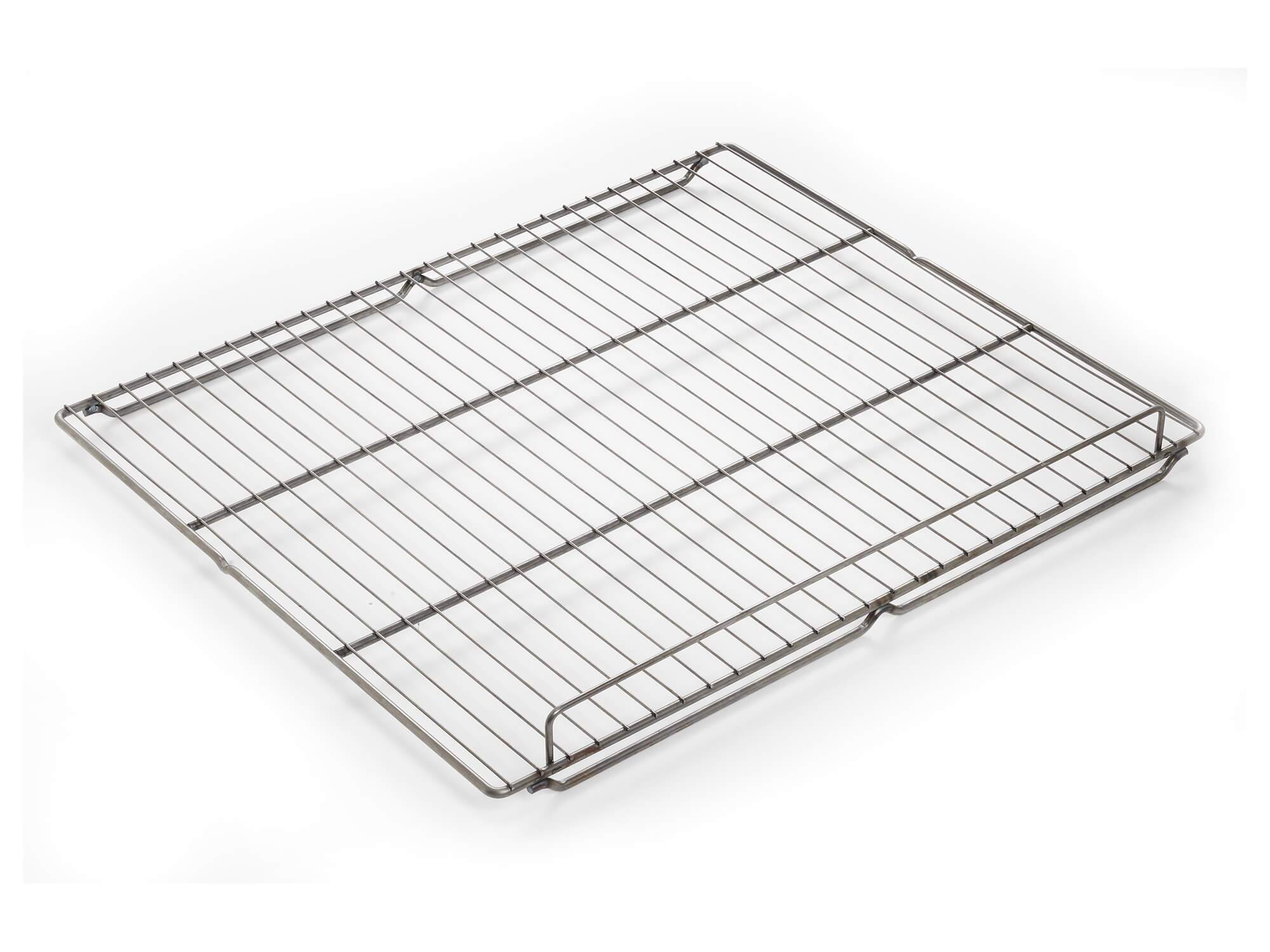

Automated machinery: examples of finished products

Visit the section with photos of all finished products

8 advantages of making machinery with Tecsal

We produce tailor-made machinery for welding and other processes, both traditional line and robotic islands.

We reproduce and implement existing welding systems

We produce in-house hardware and we program software.

In-house production of electrodes and mechanical components

We use Industry 4.0 production technologies

We support your team in calculating machinery depreciation.

We support your staff with training in operating machinery

We provide ongoing assistance or maintenance and retrofit services for existing machinery

We are manufacturers of robotic welding systems

Our solutions are of superior quality for several reasons:

- Single point of contact: we follow the customer at all stages, from consulting to design, from training to maintenance, through to the sale of welding machines and spare parts.

- Customised solutions: we are able to provide customised solutions for any kind of requirement related to the world of welding and robotic welding systems.

- Quick solutions: every need, spare part request or problem can be solved in a short time, with maximum efficiency and without having to call in third parties.

- Consultancy: we can recommend the best welding solutions thanks to our decades of experience.

- Production of customised components and electrodes: Tecsal can produce all the necessary mechanical components and electrodes, standard or customised to specific requirements.

- Industry 4.0: our welding systems benefit from all the advantages of innovative Industry 4.0 production technologies.

- Software configuration: our technicians can configure the appropriate software for the required functions. We can programme each machine or PLC by creating the appropriate work cycle sequence and graphical user interface.

- Service and maintenance: our customers can rely on the maintenance and servicing of their equipment, even remotely. We also carry out work on third-party installations.

Our method

During the design phase we will ask you to carry out preliminary tests, in order to verify the feasibility of the design or request and guide you towards improved solutions if necessary.

01Customised design

We then design the system, with the possibility of modifications during the course of production, thanks to direct connection between the design office and production.

02Production

Our technicians also take care of the programming, with the work cycle sequence according to your needs.

03Testing and installation

We take care of mechanical assembly and machine wiring.

04Training and coaching

All machinery is supplied with a comprehensive user manual.

Why implement a customised automated welding system?

The advantages of welding robots

Robotic islands and welding robots tailored to your needs

Types of automated machinery

- simple automations

- finished machine customisation

- complete traditional lines

- complete automated lines

- custom solutions

- solutions for product industrialisation

- modifications of existing installations

- design of fully customised automated machinery

- design of automated systems grouping several processes

- design of automated welding plants for individual processes:

- resistance welding robots with spot welders

- resistance welding robots with micro weld heads

- TIG, TIG/MAG, MMA and MIG Pulsed welding robots with arc welders

- welding robots with capacitor discharge welders

- single-process automated machinery design:

- automated handling systems

- automated plasma cutting systems

- automated assembly machines

- automated loading/unloading systems

- automated palletising systems

Why choose Tecsal

01Confidentiality

02Continuous support

03Software component certification

A solution for every need

Our experts are available to guide you according to the practical need or idea you have in mind. We will ask for the information you need to facilitate the realisation of the system, such as advice and technical information on your product and proven production processes, so that you do not fall back on design mistakes you have already made before.

Solutions designed for others may not be effective for your company. If you have previously purchased a system that was not built with your company’s actual production process in mind, you may end up with sub-standard manufactured parts, sub-standard cycle times, a sub-standard appearance. Looking for initial savings can in the long run result in risks of loss that should not be underestimated. For major investments, it is always better to rely on an expert who can guide you towards the best solution and guarantee you an effective, safe and durable system.

In order to operate a plant, you need to be familiar with robots and PLCs (Programmable Logic Controllers), understand how automated machinery works, what its strengths and weaknesses are, have a minimum of familiarity with HMIs (Human Machine Interfaces) and notions of mechanics to be able to operate the machinery.

If your staff needs to refresh or strengthen these skills, the training courses provided by Tecsal can fill any gaps.

There are many companies that can benefit from our solutions: e.g., companies that carry out wire machining in oven and refrigerator grills, the electrical appliance sector, the assembly of mechanical components, the resistance sector, packaging, handling, robotics, eyewear and many others.

Workers gain in safety, thanks to the use of light curtains and safety sensors certified in compliance with safety regulations.