Toll mechanical manufacturing

Improve performance and cut time

for your machining operations: no more waste and rework

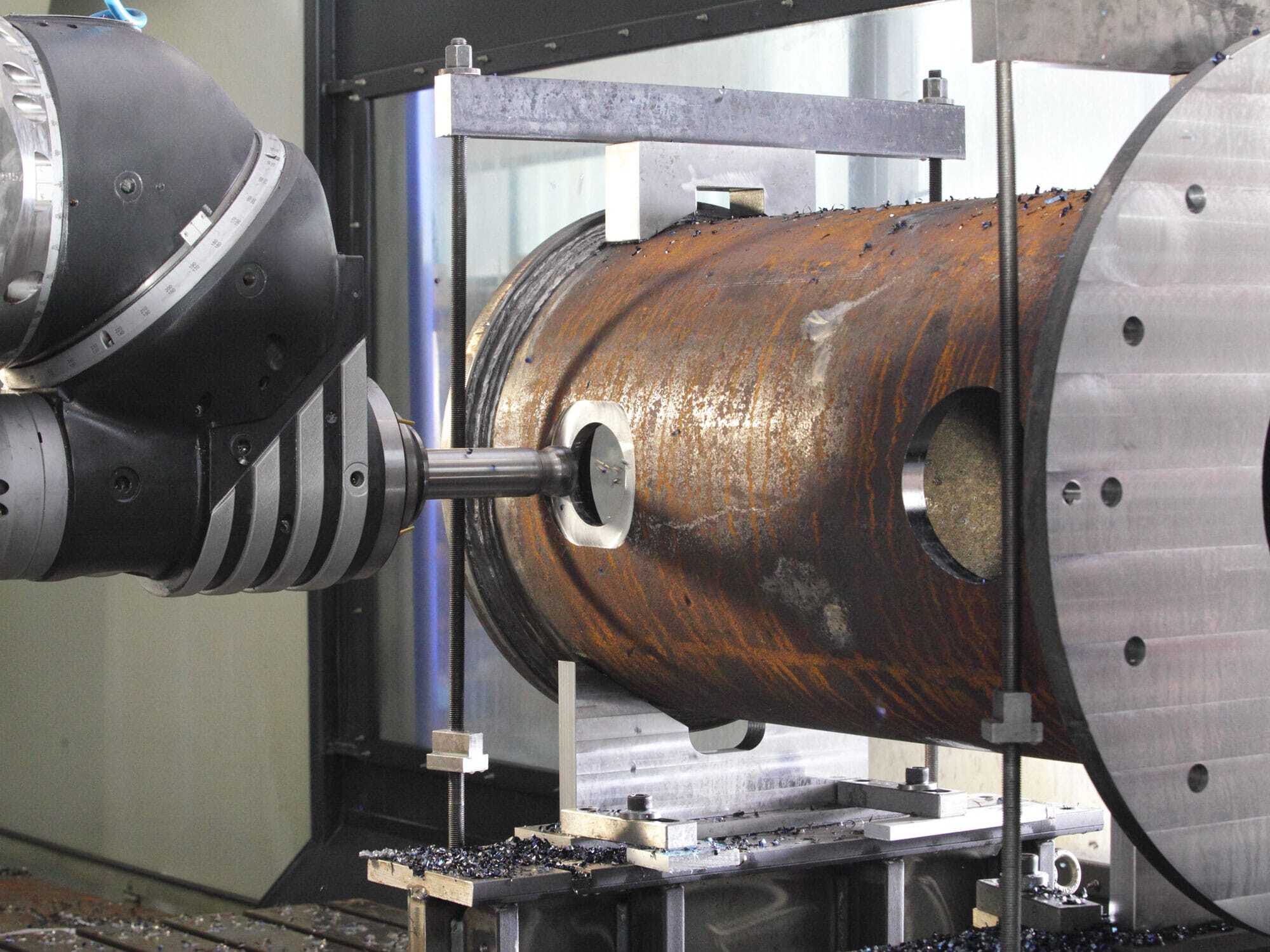

Machine park: our production departments

We cover all needs in CNC milling, wire EDM, CNC turning and grinding.

See the list of machinery available in each production department.

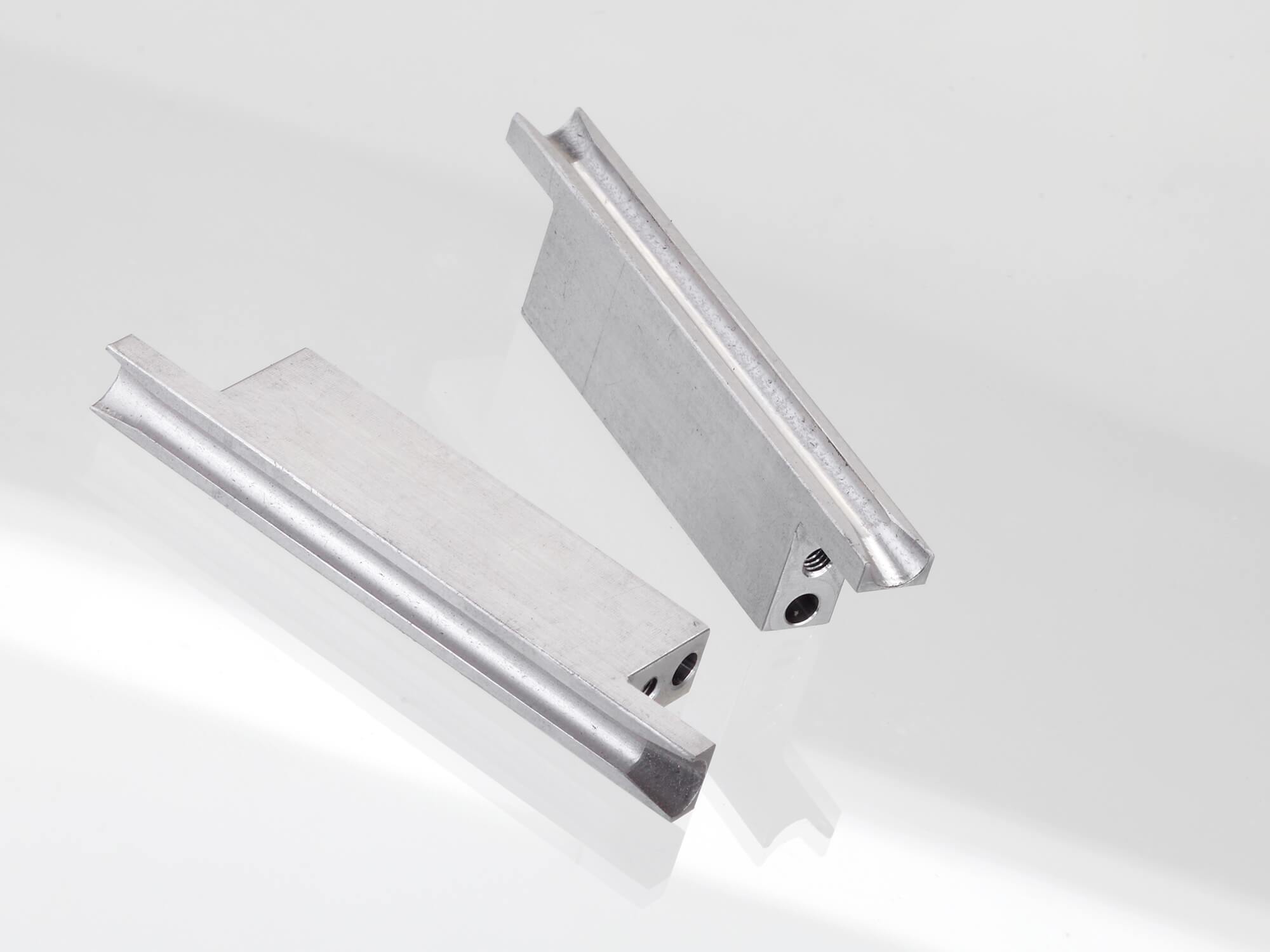

Mechanical machining: examples of finished products

Visit the section with photos of all finished products

8 advantages of Tecsal mechanical machining

Express quality mechanical machining thanks to 5-axis machines and in-house management of each phase

We also produce components in small series

We can recreate parts from samples

We deliver products quickly, even at short notice

We have a large machine park that is always kept up-to-date and has the latest CAD/CAM 3D software

We follow every stage from design to finished product

We guarantee a high level of quality control

We work on any type of material, including tungsten and synthesised alloys, and any type of measurement, to the required standard

A machining company to deliver you finished products

Tecsal can take over all the machining necessary to deliver a finished product, whether it is a single component or a welding system.

We guarantee maximum support in all phases of machining, from the design phase and following the entire production, assembly and testing cycles, guaranteeing quality and maintaining schedules.

Why choose precision toll mechanical manufacturing?

Are you looking for a CNC turning service or other mechanical machining?

Does your company not have an in-house machine shop and needs to carry out machining such as milling, wire EDM, grinding or toll CNC turning?

Tecsal performs all types of toll precision machining and produces a wide range of mechanical components and parts, both large and small.

We specialise in the production of mechanical components even in small series, and in the manufacturing of mechanical systems or their spare parts.

We provide our customers with a large CNC machine park and a highly specialised team.

The constant updating of the machine park and the know-how of the team allow for maximum flexibility according to requirements and the best result for our customers.

We guarantee quality mechanical manufacturing.

Why choose Tecsal

01Speed and efficiency

02Confidentiality

03Continuous support

04Trusted partners

A solution for every need

We can produce spare parts for your company’s systems or build components for the systems you sell.

Tecsal manufactures electrodes for spot welders capable of processing these materials in-house. We produce custom-made electrodes with the required taper.

There are many companies that can benefit from our solutions: e.g. manufacturers of automated systems, carpentries, subcontractors lacking certain machinery, workshops